Best Sellers

-

HP Versatile - C8842A€34.70 €28.92 As low as €32.96HP Versatile - C8842A€34.70 €28.92 As low as €32.96

UK Stock Now Available

The HP C8842A Versatile Black Ink cartridge is a reliable and affordable HP Original product. This product has been targeted for use by companies in the mailing and print sectors. The HP Versatile allows you to achieve printing at high speeds and produces outstanding results.

-

HP 789 Compatible Latex Ink CartridgesAs low as €111.30 €92.75HP 789 Compatible Latex Ink CartridgesAs low as €111.30 €92.75

The Compatible HP 789 Latex ink comes in 775ml compatible cartridges that match OEM quality and performance, they are Plug & Play, so you don't have to either flush your machine or adjust the colour profiles you are already running. Available in Black, Cyan, Magenta, Yellow, Light Cyan and Light Magenta

-

Compatible Canon PFI-1700As low as €129.00 €107.50Compatible Canon PFI-1700As low as €129.00 €107.50Please be aware that we do not hold stock of this product and therefore delivery time may take 5-7 days.

These Canon Compatible PFI-1700 700ml Ink Cartridges contain water-based pigment ink. This STS water based pigment ink is 100% Compatible and Mix & Match with the Canon PFI-1700 range and compatible with the following printers: Canon imagePROGRAF Pro-2000, 4000, 6000.

-

HP Q2299A Carriage Assembly€11.03 €9.19HP Q2299A Carriage Assembly€11.03 €9.19

The HP Q2299A Carriage Assembly is an inkjet printhead mounting and implementation solution for the HP TIJ 1.0 C6602A (black) print cartridge. This is a genuine HP part that has been tested extensively to meet HP's quality and compatibility standards and it's guaranteed to function correctly in your printer.

-

Colortrac Smart LF Scan! 24€2,731.56 €2,276.30Colortrac Smart LF Scan! 24€2,731.56 €2,276.30

The Colortrac Smart LF Scan! 24 Scanner is the world's first self-contained scanner for large format drawings, plans and documents up to A1 in size. The Colortrac Smart LF Scan! 24 Scanner is supplied with a toughened carry case and weighing only 5.2kg, this allows you to move the device to multiple sites and locations with ease.

-

HP 2580 B3F58B Black Solvent€73.08 €60.90 As low as €67.60HP 2580 B3F58B Black Solvent€73.08 €60.90 As low as €67.60

The B3F58B HP 2580 Black Solvent Ink was originally designed for coding and marking on blister foils, however, after general use in a wide range of customer applications, the B3F58B HP 2580 Black Solvent Ink has proved to have excellent performance on pretty much all the common packaging and print non-porous materials, plus metal!

Our Risograph Range

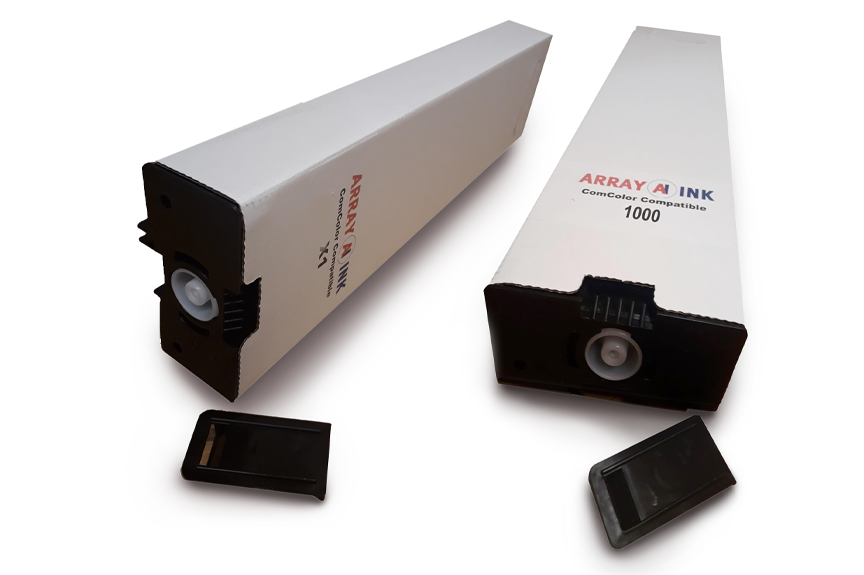

Riso ComColor Bag in Box

Riso HC5000, 5500 & 5500R